Silicone storage bag

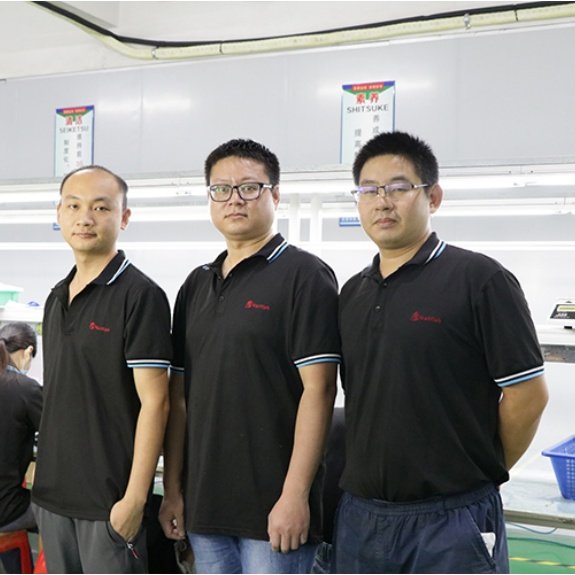

Provide OEM processing for factories, trading companies, and cross-border e-commerce

Custom Silicone Bags

Looking for eco-friendly custom silicone bags for food storage, packaging, or promotional use? HaoTian is your one-stop silicone bag supplier, offering complete custom molding solutions from concept to market.

As a leading silicone bag manufacturer and molding solution provider in China, the HaoTian team collaborates with brand owners, product managers, developers, and senior designers across industries. We provide OEM/ODM services that include silicone bag design, prototyping, contract manufacturing, printing, and packaging—serving sectors such as baby care, stationery, homeware, promotional merchandise, IP licensing, and cosmetics.

Partner with HaoTian to create durable, sustainable, and brand-ready silicone bag solutions tailored to your business.

- HaoTian is a molded silicone products technical support provider

- Our factory is certified by SA8000(SGS), ISO9001, ISO14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney.

- All the materials that we used have the certification: FDA, LFGB, and ROSH. REACH, PAHS, and Phthalate all tested by SGS., etc.

- All the products pass: FDA 21 (USA Standard), CPSIA, CP65, LFGB German §31, EN-71 and (EU Standard) or Others.

Customized service:Your silicone bag, We build it , box it.

HaoTian’s silicone bags are fully customizable—tailored in material, size, design, capacity, function, structure, shape, color, logo, pattern, packaging, and labeling—to ensure the success of your silicone project.

We also offer a wide range of silicone bag models in various sizes, shapes, and structures, along with custom logos and packaging to match your brand perfectly.

Material

Our experienced engineers will recommend the most suitable raw materials based on your specific requirements—such as liquid or solid silicone, tensile and tear strength, and compliance with standards like FDA, LFGB, or medical-grade specifications from various brands. If needed, antimicrobial agents can also be added to meet sterility and hygiene standards.

Custom Size & Shape

You can fully customize the functionality, shape, size, and embossed or debossed logo of your silicone bags by developing new tooling. The structure and design—whether flower, square, triangle, star, or other creative forms—can be tailored to match your specific requirements.

As a trusted manufacturer of a wide range of silicone bags for cosmetics, milk storage, stationery, and more, we provide custom-branded packaging and offer various models in diverse shapes, sizes, and configurations.

All customized silicone bags are made from food-grade, BPA-free silicone that is eco-friendly, heat-resistant, and safe for everyday use.

Custom silicone bag color and printing

You can customize the color of your silicone bags based on the Pantone color chart. Popular options include Translucent, White, Tea Green, Morandi Green, and Grey.

If needed, HaoTian also offers double-color and marble-color silicone bags to suit your design preferences.

With an in-house printing workshop, HaoTian provides multiple branding options including Laser Engraving, Silk Screen Printing, Heat Transfer Printing, Water Transfer Printing, In-Mold Decoration, and Digital Printing to bring your patterns and logos to life.

Custom silicone bag brands, labels and package

HaoTian offers tailored packaging solutions for silicone bags, providing end-to-end support including design, development, assembly, and inspection. Our one-stop service ensures that the final packaging not only protects the product during transportation but also enhances its retail appeal.

Our dedicated packaging team ensures that every silicone bag is delivered to end sellers in excellent condition, meeting the highest standards of quality and presentation.

All of HaoTian’s silicone bags are a healthier, eco-friendly alternative to plastic. Made from 100% reusable, food-safe silicone, each bag helps reduce plastic waste and keeps harmful materials out of our oceans.

Custom silicone bags from HaoTian are safe, food-grade, and highly versatile—perfect for organizing and protecting your everyday essentials while supporting a more sustainable lifestyle.

Silicone Bags Making Experience

As a silicone product manufacturing factory in China, HaoTian is a leading supplier of reusable silicone food bags. We produce and supply a wide range of silicone bags—including silicone storage bags, reusable food bags, silicone pencil cases, pouches, cosmetic bags, and makeup bags—for brands, wholesalers, and retailers around the world.

Custom Small Silicone Bag

Custom Silicone Pastry Bags

Custom Silicone Zipper Bag

Custom Silicone Water Bag

Custom Logo Printed Silicone Bags

Custom Silicone Cosmetic Bag

Custom Silicone Kneading Bag

Custom Silicone Collapsible Pencil Bag

Custom Silicone Tea Bag

Custom Silicone Storage Bag

Custom Silicone Snack Bag

Custom Silicone Rubber Bag

Custom Silicone Hot Water Bag

Custom Folding Silicone Water Bag

Custom Silicone toiletry & makeup bag

Custom Silicone Reservoir Bag

Reusable silicone bags are perfect for on-the-go use, food storage, freezing, and even cooking. Ideal for soups, leftovers, cereals, pasta, flour, and perishable items like fruits and vegetables. Made without BPAs, phthalates, PVC, lead, or latex, these bags are safe, durable, and long-lasting. Featuring a secure zip sealer, they are plastic-free, microwave and oven safe—an eco-friendly and practical solution for everyday storage needs.

100% FDA or LFGB standard

All silicone bags we produce are made from 100% FDA (U.S. food-grade) or LFGB (EU food-grade) certified silicone—BPA-free, environmentally friendly, sustainable, and recyclable.

Our molded silicone bags are easy to clean, quick-drying, waterproof, and antibacterial. By choosing silicone, you help reduce environmental impact, cut down on disposable plastic waste, and contribute to protecting our planet’s forests.

Custom Silicone Bags making process

The Whole Process to create Your silicone bags

The process of customizing silicone bags involves several steps to create personalized and branded silicone bags. Here’s a general overview of the customization process:

Design Concept:

Clarify your design concept and create a 3D structure for the silicone bags based on your vision — including preferred size, shape, color, and any special features or patterns you'd like to incorporate.

Material Selection:

Select either Liquid Silicone Rubber (LSR) or solid silicone as the base material, ensuring it meets all relevant safety and quality standards for your intended application.

Prototype Development:

Develop a prototype or sample of your custom silicone bags—this step helps you assess the design, fit, and functionality before moving forward with mass production.

Custom Printing or Branding:

If you'd like your silicone bags to showcase logos, artwork, or branding, we can incorporate your design using CNC engraving on tooling, screen printing, heat transfer printing, in-mold decoration, or other suitable methods to apply patterns directly onto the sleeves.

Tooling and Molding:

Develop molds or tooling based on the finalized prototype. These molds enable consistent and precise production of silicone bags in the desired shapes and sizes throughout the manufacturing process.

Material Mixing and Preparation:

Prepare the silicone material by blending it in line with the manufacturer’s specifications. This includes mixing in necessary additives and color pigments to achieve the desired properties and final color.

Molding and Shaping:

Transfer the prepared silicone material into the molds. Based on the product design, this process may utilize Liquid Silicone Rubber (LSR) molding, co-injection dripping, or silicone compression molding to ensure precision and consistency.

Curing and Cooling:

Let the silicone bags cure and cool naturally within the molds. The curing duration may differ based on the silicone type and the thickness of the final product.

Demolding:

Carefully remove the cured silicone bags from the molds, making sure they retain their designed shape and structure.

First Quality Control:

Inspect each silicone bag for defects like air bubbles, surface irregularities, or color inconsistencies. Any items that don’t meet quality standards are removed from the batch.

Post-processing:

Proceed with the silicone bag production, followed by essential post-processing steps such as trimming, grinding, polishing, spraying, and thorough inspection to ensure premium quality and a flawless finish.

Secondary vulcanization:

Secondary vulcanization is required for inspected products to meet FDA or LFGB standards. This involves baking in an oven for 2–4 hours. For LSR silicone bags, this step may be optional depending on the material and application.

LOGO or Pattern printing if needed:

Apply the design using laser engraving or printing. In some cases, the logo can be directly integrated into the silicone tooling for a more permanent and precise result.

Cleaning and Packaging:

Clean the silicone bags thoroughly to eliminate any residue or impurities. Then, pack them based on your specific requirements—whether as individual units or in sets—ensuring they are presentation-ready for your market.

Final Quality control and testing:

Once the silicone bags production is complete, a final quality check is conducted to ensure all items meet your specifications and standards before shipment.

Warehouse and Shipping:

The final OQC for all personalized and branded silicone bags is completed, and the products are safely stored in our warehouse—ready for dispatch to your destination.Shipping options available:

Courier (DHL/UPS/FedEx): Estimated transit time 3–8 days

Air Freight: Typically takes 10–15 days

Sea Freight: Delivery time ranges from 30–50 days depending on location

Please go through the “How to create silicone bags”to know more details.

How To Order your Silicone Bags

HaoTian Group is a dedicated silicone bag molding factory, ready to support all your custom silicone bag needs with high-quality solutions tailored to your project requirements.

We guide you through the entire process—from silicone bag design, tooling development, and mold manufacturing to full production and final delivery—ensuring every detail aligns with your expectations.

Here’s what the path to customized silicone bags looks like for our customers:

Step 1: Custom Needs And Budget

Your company’s needs and budget will determine the type of silicone bags you can order and the level of customization each one receives. Once your budget is set, it’s the perfect time to contact HaoTian Group. We’ll guide you in the right direction to help you create the ideal custom silicone bag solution for your brand.

Step 2: Customer Idea, Design, Sample

Simply provide us with a CAD file containing the specifications of your silicone bag project, and we’ll handle the rest. If you don’t have a CAD file, no problem—we can create the design based on a hand sketch, drawing, photo, or sample, and develop a prototype mold tailored to your vision.

Step 3: Prototype Tooling To Get The Silicone Products Samples

If you’re developing a new silicone bag and unsure about the final result, we can create a prototype to help you evaluate its fit, functionality, and appearance before committing to mass production tooling. Once you’re satisfied with the prototype, you can move forward with mold development confidently.

This approach minimizes risk, allows you to test the market with a low upfront investment, and makes design adjustments much easier at the early stage—rather than after the tooling is completed.

Step 4: Mass Production Tooling

Once you’re satisfied with the silicone bag samples, we will proceed with mass production tooling based on the finalized sample details and communications—all completed in our in-house tooling workshop to ensure accuracy and efficiency.

Step 5: Silicone Molds And Mass Production

If you’d like to test the market first, you can start with a small order—our minimum order quantity (MOQ) is just 3,000 pieces. As your demand grows, you can scale up to any production volume. We also offer cost-effective silicone bag molds made from aluminum (AL) material to suit your project requirements.

Once you confirm the silicone bag samples we’ve made, the next step is to approve the golden samples or share any necessary revisions. Upon final approval, we’ll begin processing and manufacturing your silicone bags.

All silicone bags undergo trimming and quality control in our dust-free workshop. We perform 100% QC before packaging to ensure every molded product meets your expectations. At HaoTian, we promise a well-organized workflow and on-time delivery of your custom silicone parts, exactly as specified.

Step 6: Storage And Delivery

We have a dedicated warehouse for product storage before shipment, available upon request.

The final stage is also the most exciting — delivery! It’s a moment we look forward to, as it reflects our commitment to serving customers. Once production is complete, we’ll arrange pickup, shipping, or delivery of your silicone molded products based on your location and preferred method.

Why Choose HaoTian As Silicone Bags Supplier

12 years’ custom silicone products experience

Our experienced engineers and deep market knowledge allow us to understand the specific product and quality requirements of wholesale customers across diverse industries.

Safety Factory

HaoTian is proudly certified by SA8000, ISO 9001, ISO 14001, BSCI, SEDEX, BRC, FCCA, NBCU, and Disney. Our factory has been audited and approved by globally recognized third parties and trusted by Fortune 500 companies—ensuring proven reliability and strong manufacturing capabilities you can count on.

100% safe raw material

We use 100% food-grade, high-purity platinum silicone—safe, non-toxic, and eco-friendly. All materials are certified by FDA, LFGB, RoHS, and other standards like REACH, PAHs, and Phthalates upon request.

One Stop Service from design to whole process manufacturing

HaoTian has an in-house mold workshop with experienced design engineers and a full post-processing facility. From design and tooling to mass production, everything happens under one roof—saving you time, reducing costs, and minimizing risks from dealing with multiple suppliers.

Stable production capacity

With 46 advanced molding machines, HaoTian produces 100,000–150,000 silicone trays daily and exports to 40+ countries—ensuring fast delivery and no risk of stockouts for your business.

Wholesale OEM/ODM Services

HaoTian offers complete OEM/ODM services with flexible wholesale customization—covering design, color, and packaging to match your unique product needs.

Strict Quality Control

A full-process quality control system—from product development to final production—ensures that every silicone product delivered matches the approved prototype and meets customer expectations.

Safety products

The silicone products what Z.S.R made can pass: FDA, CPSIA, CP65, TSCA, AU, EN71, LFGB, EU 1935, CE by SGS/Intertek/TUV

Frequently Asked Questions

Yes, you can. Like ours, the current stock sample is free of charge, but the freight would be in your account. ullamcorper mattis, pulvinar dapibus leo.

We have a detailed picture displayed above. You also can send an email to request more clear information from our sales

Our products are made of 100% food grade silicone material. All the materials that we used can pass FDA, LFGB, DGCCRF. Can offer the Material certification report.

Yes, we are a professional manufacturer & exporter in designing and manufacturing high-quality LSR/SSR silicone products over 16 years. the OEM order will be accepted

2D,3D drawing, and the specific requirement.

All are welcome just contact us at once.

Customers will need to pay for a mold if you have a custom design. And the mold will belong to the customer.

Yes. Sample mold only could use for sample making. When you need to run for mass production, a mass production mold is requested.

For bulk orders we ship it by sea or by air, For small orders, we ship by DHL, FedEx, TNT, or UPS